Drive Digital Transformation with Connected Products & Services

Industrial organizations are looking to migrate from product-based business models to product-as-a-service based models. This requires unique data-driven insights into customers’ needs to better develop, sell, support, and service their products to differentiate offerings and drive growth.

Remote Asset Monitoring

Easily connect and collect accurate, real-time data from millions of assets. VIMANA’s industrial analytics capabilities bring centralized visibility and data-driven insights to monitor, manage, and maintain industrial machinery and component parts. Access information anytime, anywhere gaining knowledge on your product’s status, performance, usage, and health to enable product innovation, up-selling opportunities, and usage-based revenue models.

Connected Field Services

VIMANA enables industrial machinery manufacturers to transform field service organizations with advanced analytics and predictive insights to improve product uptime, reduce repair time, and drive service team effectiveness. Collect, analyze, and act on data to optimize maintenance processes and remotely diagnose problems, while reducing service delivery costs. Leverage data to launch new service-based aftermarket offerings for incremental revenue streams.

Connected Vehicles

VIMANA helps connected vehicle manufacturers and micro-mobility service providers quickly develop, customize, and scale a wide range of innovative connected services. Using VIMANA’s data standardization, big data analytics, and AI-based algorithms, service providers can inform decisions and get complete control over fleet operations. VIMANA provides insight for real-time location services, asset status, predicting maintenance issues, and enabling usage-based subscription models.

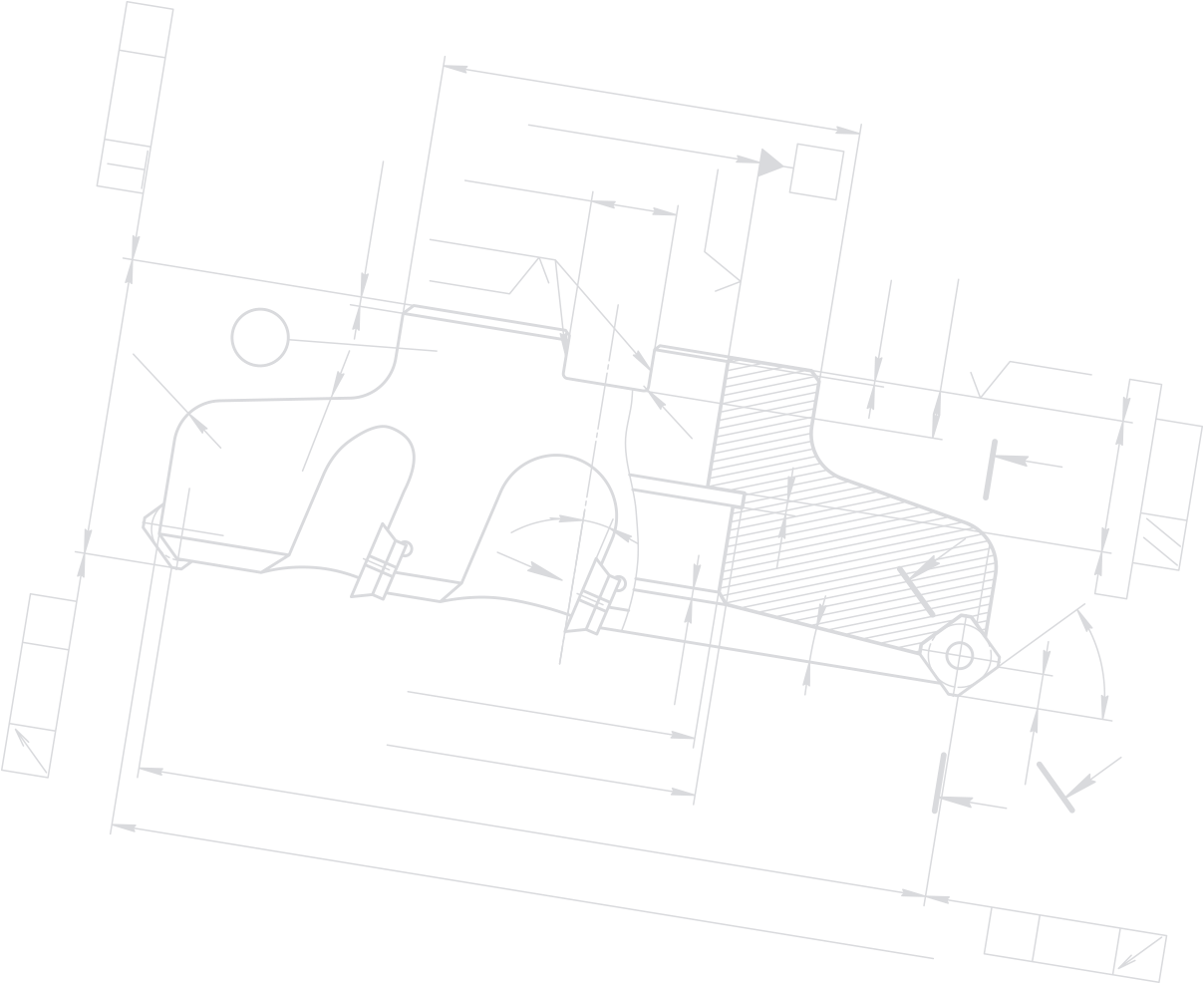

Digital Twin

Improve situational awareness and optimize planning with digital twins for manufacturing assets, processes, and connected products. Model operational technology (OT) data streams to simulate asset behaviors to anticipate potential risky or critical operating conditions to improve asset performance, production yields, maintenance, and improve quality. Create a digital twin, with product-related data to facilitate product improvements.