Enables the Journey to Predictive Maintenance

Factory equipment needs to be regularly maintained to ensure asset reliability, performance, and product quality. Current reactive break-fix

strategies and schedule-based preventive maintenance increases the risk to asset availability and high labor and spare part costs.

VIMANA Maintain, is a proven cloud-based or on-premise Predictive Maintenance solution for industrial manufacturers. This technology provides the intelligence to decide which machines to maintain, what type of activities to perform, and when to fix them. Get real-time visibility to the health of your assets. Predict equipment and tooling failures before they occur. Avoid over maintaining assets by planning preventive maintenance schedules based on data-driven insights

Maintenance Teams Achieve Immediate Value

Boost Asset Availability and Reliability

Reduce unplanned downtime by predicting machine failures before they occur and improving overall OEE.

Reduce Maintenance Costs

Decrease labor, tooling, and spare part costs by eliminating unnecessary preventive maintenance activities with usage or condition-based scheduling.

Improve Maintenance Workforce Productivity and Effectiveness

Increase in maintenance staff productivity by using data-driven insights to optimize staffing levels, reduce MTTR and MTBF.

Optimize Maintenance Processes

Extend asset life and reliability. Increase production output with more efficient and dependable maintenance processes.

Industrial Manufacturer Improves Maintenance Process Efficiency

“VIMANA Maintain predictive maintenance software transformed our preventive maintenance program. We migrated from time-based scheduling to a usage-based maintenance strategy analyzing equipment and component usage and remaining useful life. This reduced unnecessary maintenance activities and premature part replacement, saving $800,000 in one plant the first year while improving the availability of our factory equipment.”

High Precision Equipment Manufacturer

How VIMANA MAINTAIN Predictive Maintenance Software Works

- VIMANA collects and transforms large volumes of data from multiple sources: sensors, machine data, manufacturing, and IT systems.

- VIMANA Maintain provides usage, condition, and predictive analysis and visualization that deliver asset health intelligence to better manage and prioritize your maintenance activities.

- VIMANA Maintain automates alerts and triggers maintenance activities with bi-directional integration with your existing systems to action the data.

Predictive Maintenance Analytics Capabilities

Visualize and Monitor Asset Health

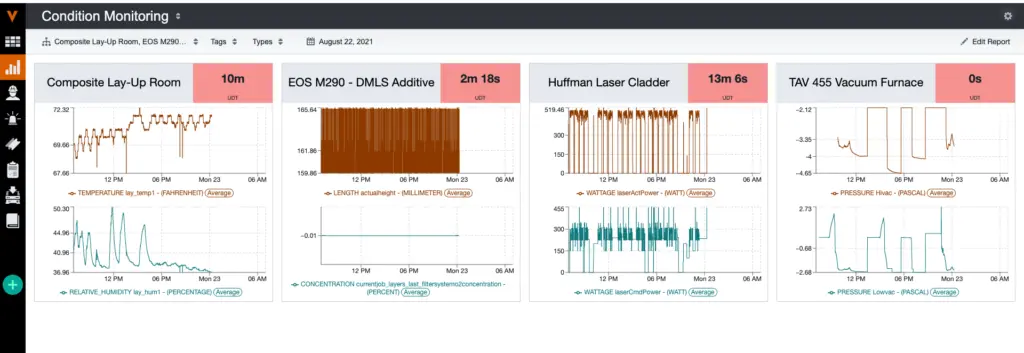

Bring visibility and monitor your manufacturing assets for better planning, scheduling, and rapid response to maintenance issues.

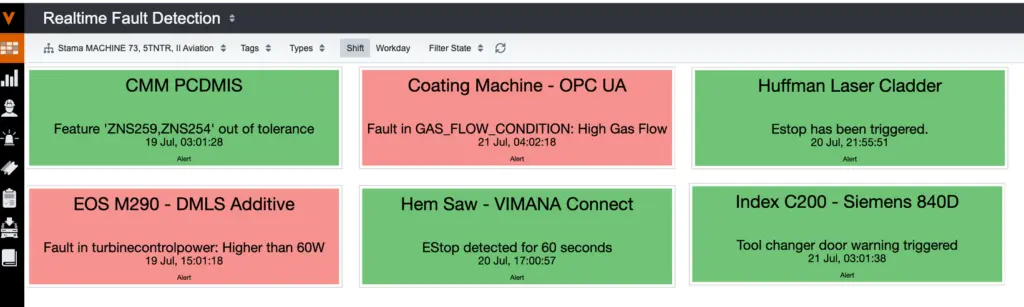

Real-time Dashboards

Bring real-time visibility to machine status, health, and process conditions with pre-built, ready-to-use dashboards. Build custom dashboards with no code, drag and drop capabilities.

Establish a baseline, monitor, and compare relevant KPIs to include the duration and frequency of downtime, faults, and warnings. Monitor remaining useful life (RUL), MTTR, MTBF, integrated with production metrics: OEE, utilization, and quality parts produced for performance improvement.

Analyze and Predict Equipment Maintenance

Root cause analysis, fault detection, anomaly detection, usage, condition-based analysis, and custom built predictive models provide various data-driven approaches to optimize maintenance processes.

Historical Reports

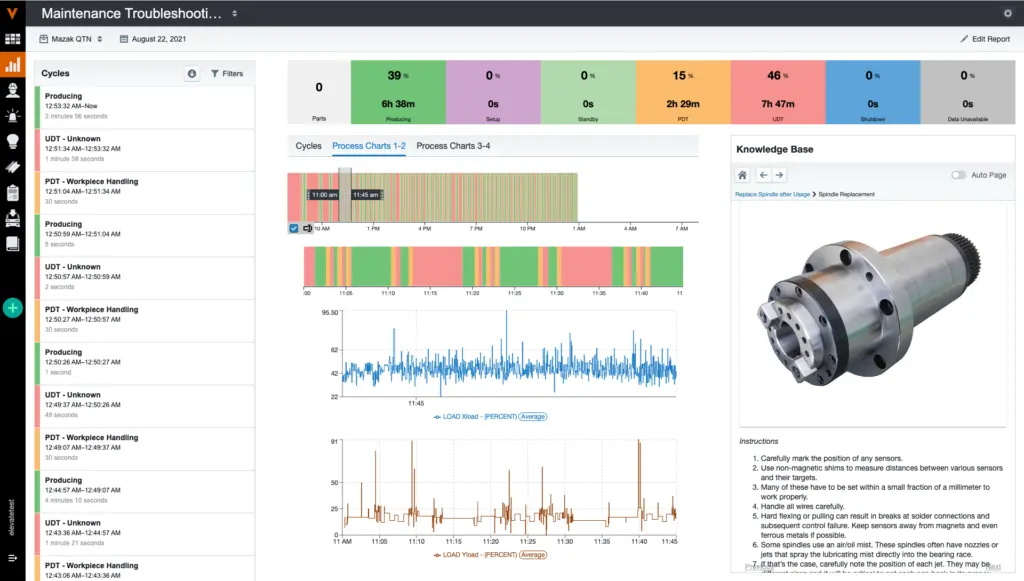

Track machine downtime and root causals with out-of-the-box, highly configurable reports that reveal insights into what happened, for how long, and why it happened to enable maintenance teams to reduce MTTR.

Understand real-time faults and warnings for machines to determine where immediate action is necessary.

Track usage based on product type, its operation, and the historical analysis of useful life. Perform maintenance tasks based on asset and tooling usage to optimize preventive maintenance staffing and scheduling.

Monitor conditions against targeted thresholds for proactive management of asset failure and product quality. Get early warnings with anomaly detection that reveals abnormal machine behavior prior to quality degradation or asset failure.

Co-innovate and build custom models to predict downtime before it occurs. Predict equipment downtimes and machine faults, tooling failures,and quality risks.

Communicate & Empower Action

VIMANA’s workforce productivity tools help you manage maintenance activities, collaborate, solve problems, and build a knowledge base to improve your maintenance team’s productivity.

Automatically and proactively notify stakeholders in real-time on asset health parameters crossing established thresholds to ignite action, control performance, and manage process change.

Communicate and track maintenance issues and requests across the workforce for rapid, closed-loop problem-solving and inform process change.

Enable paper to digital migration of the machine operators’ tribal knowledge and provides information to technicians on the operating condition of assets.

Use dynamic work instructions to provide maintenance or process instructions on-demand for operators/engineers/technicians to close skill gaps, reduce errors and improve workforce productivity.

Integrate & Automate Maintenance Process Workflow

VIMANA Maintain’s end-to-end solution provides IoT data collection and maintenance analytics that trigger manufacturing execution software(EAM, CMMS, ERP). Use secure APIs and connectors to integrate with maintenance systems to streamline workflows, minimize redundancy,and automate processes. Maintenance data is exchanged with the connectors for alerts, tickets, anomalies, faults, and metrics (MTBF, MTTR) to enable a closed-loop to completion.

Why VIMANA

Rapid Time to Value

Ready-to-use and highly configurable predictive maintenance application speeds ROI in less than 2 months.

Proven

We co-innovate with customers to build outcome based solutions. Adopted by Fortune 500 and small to medium industrial businesses.

Actionable Data From Unlimited Sources

Collects and prepares data from Sensors, Brown and Greenfield assets, IT and OT systems.

AI and Machine Learning Driven Predictive Maintenance Solutions

Choose the best approach by asset - remote monitoring, usage, condition and predictive maintenance.

Deep Industrial Vertical Expertise

No need for incremental staff to build solutions. Our expertise in discrete manufacturing results in better data, algorithms, integrations and outcomes.

Simple and Cost-Effective

Easy to implement, scale, and use. Modular and affordable.

Customer And Expert Insights

Connect, collect, and normalize data for reliable, predictive analytics.

Develop predictive models to identify when critical assets will fail.