VIMANA Field Predictive Maintenance Software For field Service

VIMANA is reshaping service delivery and enhancing customer value with IoT, cloud, big data, and predictive maintenance solutions.

How VIMANA Field Helps

Field Service Organizations from Industrial OEMs, Equipment Distributors, and MRO Service Providers look to improve after-market service delivery by transitioning from reactive to proactive service, with intelligence for predictive repair, preventive scheduling, and extending customer value with connected products.

Field Service Organizations Realize Immediate Value with VIMANA

Increase Equipment Service Profitability – Reduce Costs

Use data-driven maintenance to optimize staffing (do more with less). Decrease on-site visits with remote and proactive service. Shorten time to resolve issues. Better manage parts inventory.

Enhance Customer Satisfaction and Boost Loyalty

Improve customer service and equipment performance. Use predictive maintenance to keep machines running without failures. Get fast service by identifying and diagnosing issues sooner.

Improve Maintenance Process Efficiency

Use a data-driven approach to remote service and diagnosis, scheduling, and technician preparation of on-site visits, and automating customer requests.

Create New Value for Customers – Grow Services Revenues

Differentiate services with new support offerings and pricing levels that create continuous revenue streams. Enable new business models machine-as-a-service for customer value.

Machine Tool Manufacturer Predictive Maintenance Use Case

Machine tool manufacturers use predictive maintenance to provide insight for remote service and problem diagnosis, reducing on-site visits and time to resolution. Remote monitoring of usage and equipment conditions guides preventive maintenance scheduling, spindle replacement or rebuilds, and predicts equipment failure for proactive repair. Maintenance analytics helps OEMs improve service delivery at reduced costs.

The VIMANA Difference

Connect Products, Collect Data

Use wireless sensors and VIMANA Connect software to connect machines. Collect large volumes of data and leverage industry standards, OPC UA and MT Connect, to standardize and prepare data for advanced analytics.

Remote Monitoring and Management

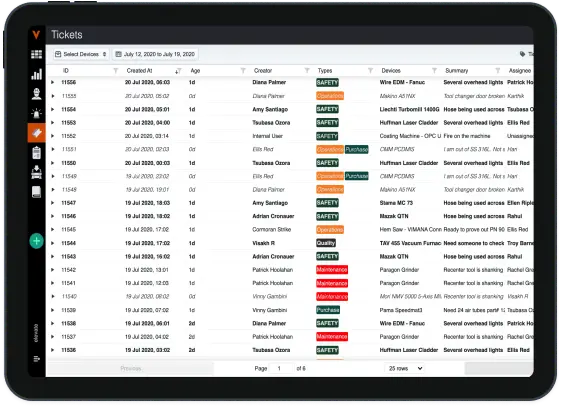

Use pre-built and customized dashboards for real-time visibility to equipment and components status, health, and utilization. Identify assets that require service. Get insight into metrics: downtime, RUL, condition parameters, etc.

Remote Service and Problem Diagnosis

Use root cause analysis, fault detection, and warnings analysis to remotely identify problems and troubleshoot issues. When on-site service is required, the insight can inform technicians and parts needed for rapid repair.

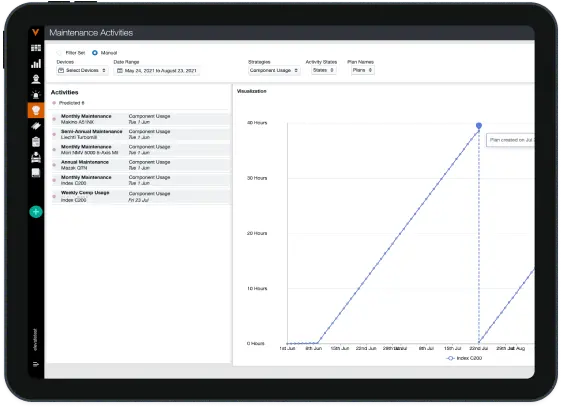

Usage-Based Preventive Maintenance

Optimize part repair and replacements and PM visit scheduling combining time and usage information. Track last PM schedule and remaining useful life to drive technician efficiency and balance device uptime and production.

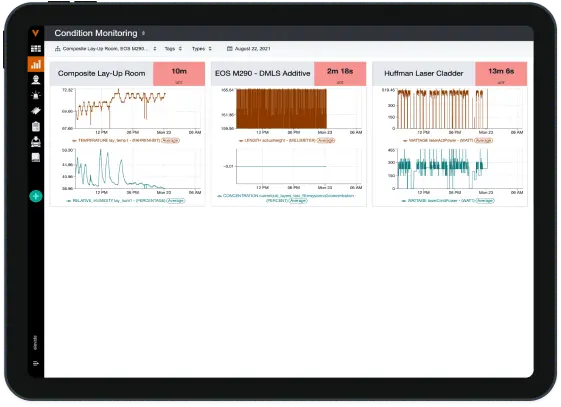

Condition-Based Maintenance for Proactive Repair

Monitor and analyze conditions, customized by device type: i.e., temperature, vibration, fan/motor RPM, current, voltage, pressure, fluid flow, path reed rates, spindle loads, hydraulic pressure, over time. See anomalous equipment behavior, irregular patterns, and trigger early warnings before failure, quality degradation, or performance decline. Use intelligence to plan proactive service.

Predictive Maintenance: Proactive Diagnosis of Equipment Health

Predict when equipment and components will fail and reduce emergency repairs. Co-innovate with VIMANA to build custom predictive models.

Communications and Process Optimization

Provide customers immediate service request processing and bring information to facilitate repair and improve first time repair rates. Data driven alerts based on rules trigger actions and integrate with field service management software to enable closed – loop maintenance activity. (FSM, CMMS, ERP, or CRM Software).

Power Your Field Service Team with Predictive Maintenance

Improve Profitability and Service Delivery Today